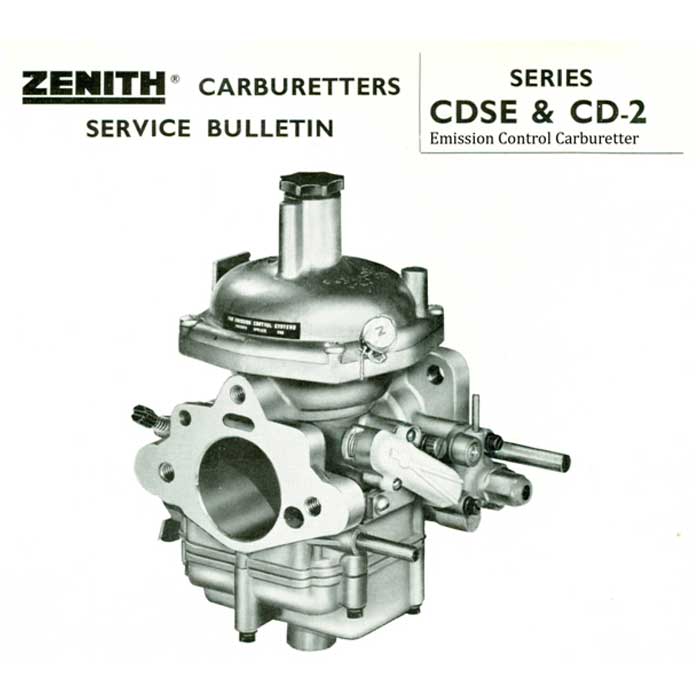

This instrument is a development of the very successful CD or constant depression carburetter, which operates on the principle

of varying the effective area of choke and jet orifice, in accordance with the degree of throttle opening, engine speed and engine load.

It is simple, compact and dustproof, with a number of special features, essential to an emission control carburetter, although the

circuits mentioned in the following text are dependent upon specification requirements.

OPERATION

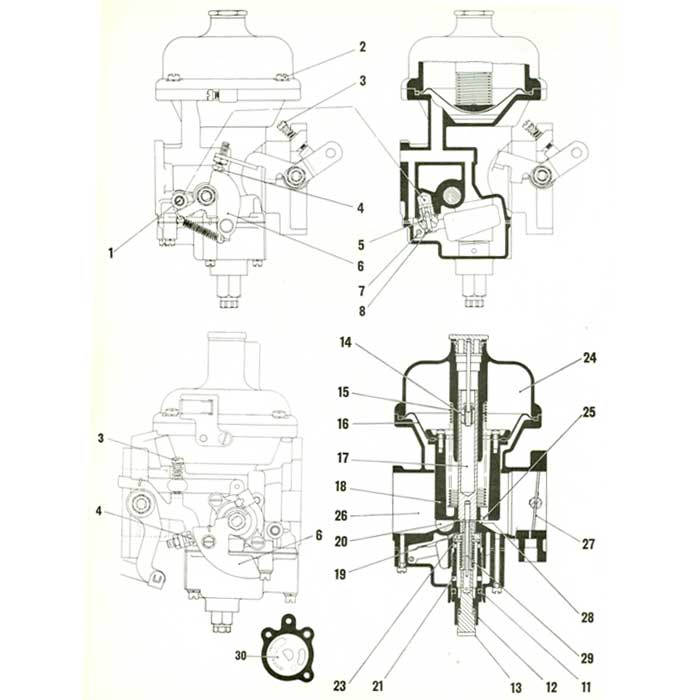

The petrol inlet 1 is a tube, accommodating a flexible fuel pipe, situated to one side of the main body. Fuel enters the float-

chamber, via a needle valve, where the flow is controlled by the needle and twin floats 2 mounted on a common arm. As the fuel level

rises, the float lifts and upward movement of the float arm and tag, closes the needle valve when the correct level has been attained.

When the engine is running, fuel is drawn from the float chamber, the float descends and more fuel is then admitted through the

needle valve. In this manner, the correct level is automatically maintained, whilst the carburetter is in action.

Fuel in the jet orifice 3 is maintained at the same level as that in the float chamber by means of cross drillings in the jet assembly.

It is essential that all carburetters for a specific application are matched exactly in respect of flow. Clearance around the air valve in

its vertical bore permits additional air to 'leak' into the mixture chamber and lower the depression. A special feature therefore is

the manufacturing tolerance compensator or leak balancing screw that is shown on the diagram as item 4.

A drilling 5 is taken from the atmospherically vented region beneath the diaphragm to meet a further drilling 6 that breaks into

the carburetter mixing chamber, down-stream of the air valve, in order to introduce an air leak. An adjusting screw with a conical

tip is then inserted into the drilling to the mixing chamber. This is capable of either completely blanking off the air bleed or permitting

flow adjustment to maximum effective diameter of the air bleed.

When set, the balancing screw is sealed with a plug which must not in any circumstances be tampered with in service.

It is essential therefore not to change the main body, cover or air valve, after the balance screw has been set and

sealed.

sealed.

STARTING FROM COLD

When the choke control on the instrument panel is pulled out, it operates a lever at the side of the carburetter; this rotates

a disc 7 in the starting device in which a series of holes of different diameters are drilled. In the full rich position, all holes will be

in communication with the starter circuit and provide the richest mixture.

Petrol is drawn from the float chamber via a vertical drilling adjacent to the central main feed channels, through the starting device

and into the throttle body between the air valve and the throttle plate. Simultaneously, the cam 8 on the starter lever will open the

throttle beyond the normal idle position, according to the setting of the fast-idle stop screw 9, to provide a fast-idle speed to prevent

stalling when the engine is cold.

As the dash-board control on the instrument panel is gradually released, fewer and/or smaller holes will provide the petrol feed

from the float chamber, thereby progressively weakening the mixture strength to a point where the control is pushed fully home.

Mixture strength is then governed by the factory setting of the main orifice and idle speed determined by the setting of the throttle

stop screw.

NOTE: The accelerator pedal should not be depressed when starting from cold.

IDLING

Fuel for idling is provided by the jet orifice, the amount being controlled by the jet/needle relationship established during manu-

facture. Idle speed is regulated by adjustment of the throttle stop screw 10, which limits the closure of the throttle when the

accelerator pedal is released.

An idle trimming screw, 11 on the diagram, is provided but THIS IS NOT AN ORDINARY MIXTURE ADJUSTING

SCREW. The purpose of this screw, is to give a very fine adjustment to compensate for the difference between a new 'tight' engine

SCREW. The purpose of this screw, is to give a very fine adjustment to compensate for the difference between a new 'tight' engine

and one that is run in. It will be seen that the idle trimming screw regulates a controlled amount of air (limited by the size of the

drilling) that can be introduced into the mixing chamber.

When the engine is new, a slightly weaker mixture can be used and the trimming screw will therefore be set initially to provide

maximum air to the mixture chamber. As the engine gradually frees off during the running-in period, this screw can gradually be

turned in a clockwise direction to reduce the air bleed until, when fully turned in, the screw will be seated.

It should be noted that to the ear there may be no detectable difference between fully 'home' and fully 'open' positions and

therefore, it should be adjusted to achieve best driveability. If available, the setting may be checked by means of a CO meter attached

to the exhaust pipe. With this aid to emission tuning during service, set the screw to give the engine manufacturer's recommended

CO level during idling.

Should idling quality deteriorate during the running-in period the screw should be rotated clockwise slowly until smooth idling

is just restored. If it is not possible to obtain satisfactory quality when the screw is fully home, the manifold and carburetter nuts

should be checked for tightness as a leak is probably occurring. ON NO ACCOUNT SHOULD THE SCREW BE OVER TIGHTENED.

NORMAL RUNNING

Mention has been made of the jet/needle relationship, which together govern correct idle mixture and mixture strength through-

out the range. One feature of the assembly is the radially located needle 12 which is biased so that the needle is permanently in

contact with one side of the jet, to ensure a consistent fuel flow from a given needle profile. The jet/needle relationship is set during

production and should not be altered.

When the throttle is opened, air flow under the air valve 13 increases and a temporary rise in mixing chamber depression is

transferred via drilling 14 in the air valve to the depression chamber 15 which is sealed from the main body by a diaphragm 16.

Pressure difference between the depression chamber and the under diaphragm chamber causes the air valve to lift. Thus any increase

in engine speed or load will enlarge the effective choke area until maximum air valve lift, since the air valve lift is proportional to the

weight of air passing beneath it. Therefore, air velocity and pressure drop across the jet orifice remain approximately constant at all speeds.

As the air valve rises it withdraws a tapered metering needle, secured in its base, from the jet orifice so that fuel flow is increased

in proportion to the greater air flow. The metering needle is a variable and machined to very close limits. It provides a mixture ratio

for all speeds and loads, in line with engine requirements, that are determined by exhaustive tests on bench and road by carburetter

specialists, working in collaboration with the engine manufacturers. To maintain correct results in respect of emissions, it is essential that

only the recommended needle is used.

THE TEMPERATURE COMPENSATOR

Emission testing has shown the need for a temperature compensator 17, operating over a wide range of air valve lift, to cater for

minor mixture strength variations caused through heat transfer to the carburetter castings. These are significant only in the context

of the extraordinary precision demanded by exhaust emission requirements.

In order to effect correction, the temperature compensator has been evolved. An air flow channel is employed which permits

some of the air passing through the carburetter, to by-pass the bridge section. With the introduction of this air into the mixing

chamber, the air valve, in order to maintain depression on its downstream side rides in a lower position, thus giving a smaller fuel

flow annulus. By adjusting the quantity of air by-passed, the degree of temperature compensation may be varied to suit a particular

application; for this purpose a bi-metallic blade 18 is used to regulate the movement of a tapered plug 19.

Two screws attach the temperature compensator assembly to the carburetter and seals are fitted to ensure that there is no leakage

at the joint with the main body.

THIS ASSEMBLY IS PRE-SET AND MUST NOT BE RE-ADJUSTED IN THE FIELD. If it is suspected of malfunction and the

tapered plug is free when carefully tested by hand (with engine both cold and hot), the compensator assembly should be changed for

another that is correctly set for the particular application.

BY PASS VALVE

Under certain conditions the rates of hydrocarbon and CO emission are extremely high when manifold depression exceeds

22"-23" Hg, the precise critical figure varying with different engines. To prevent any rise in excess of the critical figure therefore, a

throttle by-pass valve 20 is incorporated in CDSE carburetters in certain applications. This valve, provided that it is free from air

leaks, should not require attention.

The by-pass valve is preset and can only be serviced as a complete unit. It is important not to vary mixture ratio when the by-pass valve

is in operation and the circuit, shown on the diagram, feeds from the mixing chamber to the downstream side of the primary throttle.

Manifold depression acting on the diaphragm 21 will cause the valve to open when a value is reached that will overcome the coil

spring tension. Thus, variation of coil spring load will alter the operation according to requirements.

ACCELERATION

At any point in the throttle range, a temporary enrichment is needed when the throttle is suddenly opened. To provide this, a

hydraulic damper 22 is arranged inside the hollow guide rod 23 of the air valve. The rod itself is filled with special oil to within a

f' of its end. When the throttle is suddenly opened, the immediate upward motion of the air valve is resisted by the damper.

For this brief period, a temporary increase in depression over the jet orifice is achieved and the mixture is enriched. For all

requirements, use the recommended Zenith Lube-Pack to maintain correct oil level in the damper. Downward movement of the

air valve is assisted by a coil spring 24 and/or a weighted air valve.

ADJUSTMENTS

There are only three adjustments that can be made to emission carburetters in service and these are:

- Idle speed. Adjusted by rotation of the throttle stop screw.

- Idle emission. Adjusted by trimming screw in conjunction with CO meter.

- Fast-Idle. Adjusted with fast-idle screw.

Adjusting and Synchronising Multi Carburetter Installation

Loosen the clamping bolts on the throttle spindle couplings between the instruments. Next, unscrew the throttle stop

screws to permit the throttles in each carburetter to close completely, then screw in the throttle stop screws to a point where the

ends of the screws are just contacting the castings. Rotate the stop screws 11 complete turns each, to open the throttles an equal

amount and provide a basis from which final speed of idle can be set.

Note: Ensure fast-idle screw is clear of cam, otherwise incorrect synchronising will result.

Check that cold start levers are fully off against the stops with dashboard control pushed in. Adjust coupling and control wire

as necessary. Start engine and warm-up to normal running temperature. Check synchronising of throttles with suitable instrument,

or "tube to ear" method, at each intake, then tighten clamping bolts on throttle coupling.

Finally, adjust fast-idle stop screw in accordance with setting details for the particular application and lock securely with lock nut.

Note: Remember that the idle quality depends to a large extent upon the general engine condition and such points as tappet adjust-

ments, spark plugs and ignition timing should be inspected if idling is not stable. It is also important to eliminate any leaks at manifold

joints.

Float Height

When correctly set and with the carburetter inverted measure to the highest point of the floats above the face of the main body

with the fuel inlet needle on its seating. The correct measurement is 16-17 mm. with gasket removed.

Great care must be taken not to twist or distort the float arms, to ensure a constant fuel level. Should it be necessary to reset the

float height, this can be carried out by bending the tag which contacts the end of the needle. Care should be taken to maintain the tag

at right angles to the needle in the closed position.

FAULT FINDING

Service complaints can generally be broken down into three main headings which are, erratic or poor idling, hesitation or flat

spot and heavy consumption. Under these headings therefore, possible causes are put forward together with rectification procedure, although during the warranty period this work must be carried out by a dealer authorised to service vehicles equipped with emission control power units.

Erratic or Poor Idling

- Incorrect fuel level caused by maladjusted floats and/or worn or dirty needle valve. Check float height and wash needle valve in

clean spirit. Replace needle valve if worn. - Air valve sticking. Check free movement of spring-loaded metering needle, clean air valve rod and guide. Lubricate air valve

rod and guide with a few drops of light oil. - Metering needle incorrectly fitted. Ascertain that the metering needle is fitted and positioned in accordance with the vehicle

manufacturer's specification. Check identification to ensure that the correct needle is fitted, and also the housing has not been

distorted by over-tightening the needle locking screw. - Partially or fully obstructed diaphragm and float chamber ventilation holes. Check that air cleaner element and case are correctly

aligned and that gaskets are not causing obstruction. - Diaphragm incorrectly positioned or damaged. Check location with depression chamber cover removed. The two depression

holes at the base of the air valve should be in line with and towards the throttle spindle. Replace diaphragm if damaged. When

replacing depression chamber cover, the damper ventilation boss must be towards the air intake. - On multi carburetter installations, throttles not synchronised. Re-set correctly.

- Leakage from vacuum pipe connections. Re-make connections as necessary.

- Temperature compensator not operating correctly. With engine and carburetters cold, remove cover from temperature com-

pensator assembly and ensure that the tapered valve is seated. Check operations by carefully lifting the valve off its seat; when

released, the valve should return freely. If any damage should have occurred that prevents the mechanical operation functioning

correctly, the compensator unit should be changed. - After reasonable service, inspect throttle spindle end seals and replace if necessary.

- Leakage at induction manifold joints. Re-make joints facing-up flanges as required.

Hesitation or Flat Spot

Possible causes are as listed under 'Erratic or Poor Idling' but with the addition of the following:

- Damper inoperative. Check oil level and top-up using the recommended Zenith Lube-Pack.

- Air valve return spring missing or wrong part fitted. Identification is by spring wire diameter and number of coils, and in service

by colour coding. Check against setting data for the particular application.

Heavy Consumption

Whilst any points that have been covered under the previous headings can contribute to heavy fuel consumption, a check should

also be carried out to ensure that there is no fuel leakage from the float chamber joint or sealing plug '0' ring due to damage of either or

both of these parts.

SPECIAL PARTS

Although already covered in the previous text, it is thought worthwhile to repeat the items which must not be changed or

adjusted in service to maintain exhaust emissions within the legislated limits imposed.

Note: If more than one carburetter is fitted do not change parts from one carburetter to another as each unit has its own matched

components.

ITEMS THAT MUST NOT BE CHANGED

- The jet assembly.

- The air valve.

- The depression chamber, cover.

- The position of the metering needle.

ITEMS THAT MUST NOT BE ADJUSTED

- The temperature compensator.

- The air valve return spring loading.

- The by-pass valve spring loading.

carburetter must be replaced. In the case of (d) it is permissible to replace the metering needle provided that the procedure outlined

is faithfully followed and the correct type only is used.

Air Valve/Diaphragm Assembly

A bead and locating tab is moulded to both the inner and outer radii of the diaphragm to ensure correct positioning of this item.

The diaphragm is secured to the air valve by a ring and screws with lock washers and it is necessary to ensure the bead is correctly

located and the screws tightened fully.

Location for the bead and tab on the outer radii of the diaphragm is provided by a location channel at the top of the main body.

It is important that location beads and tabs are accurately positioned.

When refitting the suction chamber cover, place it accurately so that the screw holes line up with those in the main body, this

will prevent any disturbance of the located diaphragm.

Air Valve Rod and Guide

The air valve rod and guide must be kept clean and should not be handled unduly to avoid corrosion. A few drops of light oil

should be applied to the rod before refitting.

Float chamber Removal

To prevent the leakage of petrol from the float chamber, a rubber "0" ring 25 is situated between the jet cover and the float-

chamber spigot boss.

Care should be taken when removing the float chamber to avoid damage to the faces and floats.

A CARBURETTER IS AN ACCURATE AND DELICATE INSTRUMENT