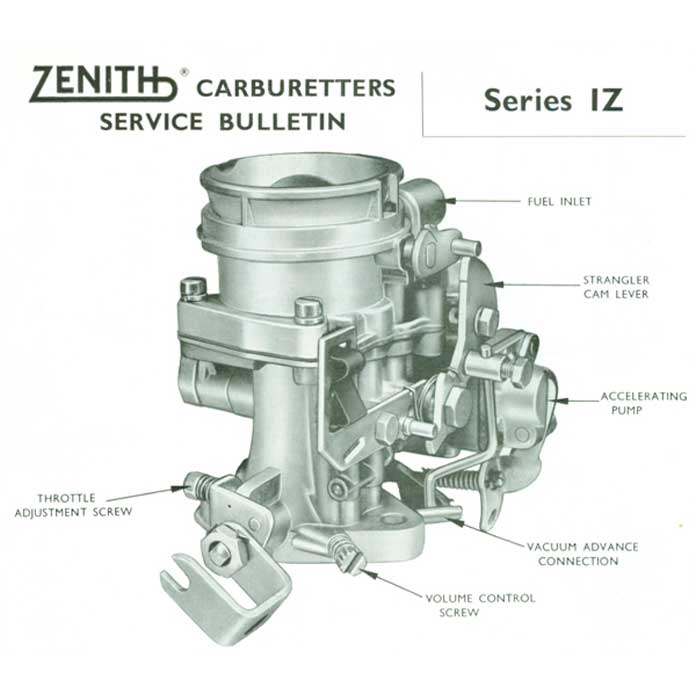

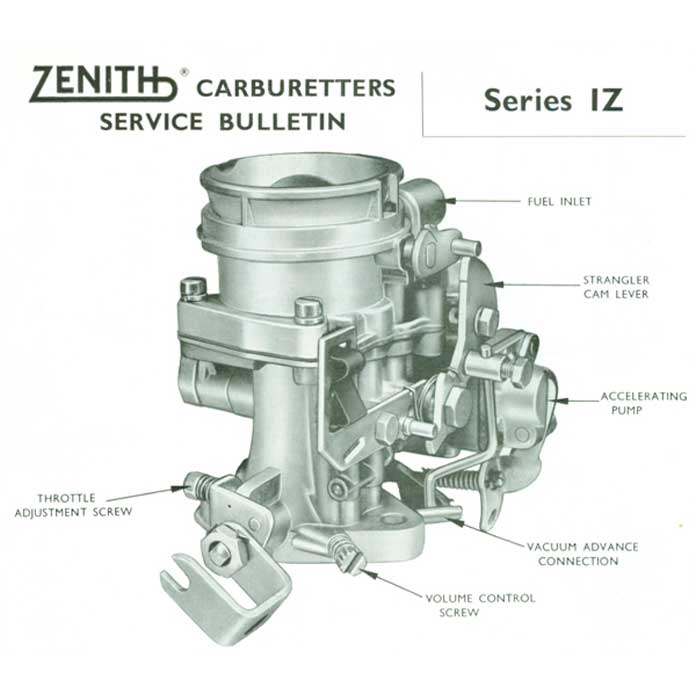

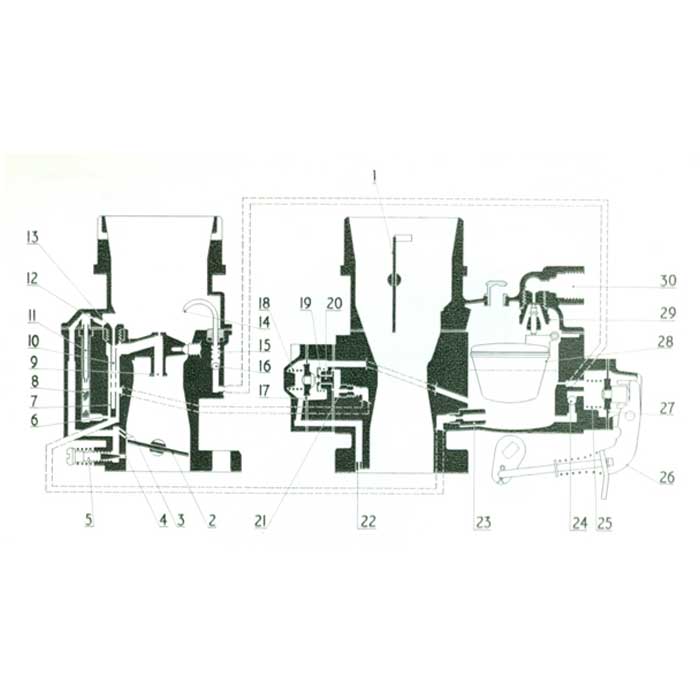

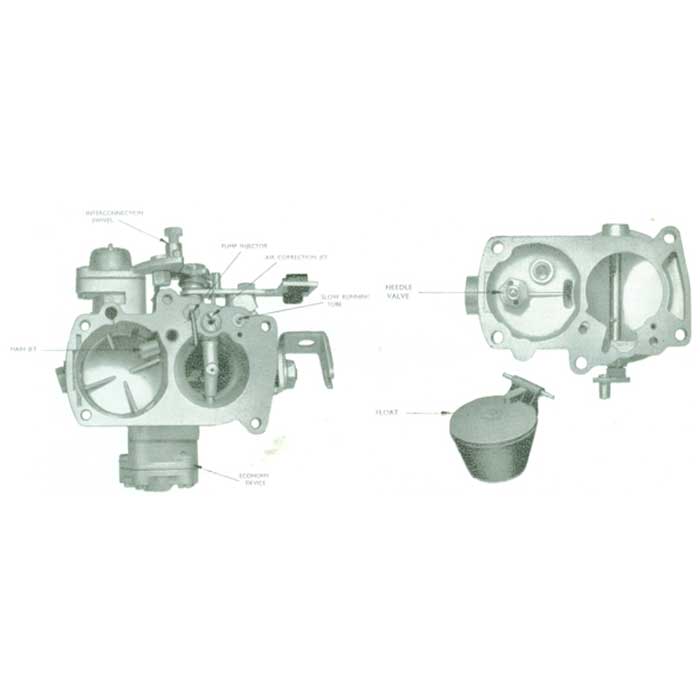

The IZ carburettor is a downdraught instrument of compact design, incorporating fully-automatic strangler for cold starting, diaphragm type accelerating pump, providing powerful acceleration, depression-operated economy device to allow maximum economy at part throttle cruising and volume control of idle mixture. A filtered slow-running tube, together with carefully positioned jets and passages, combine to provide maximum protection against dirt or foreign matter upsetting performance. Two die castings form the major parts, the upper, or float chamber cover incorporates the air intake and fuel inlet and the lower, or main body, includes float chamber, choke tube and fixing flange which bolts directly to the engine induction manifold. These two parts are held together with five screws. At present, the throttle bore size is 30mm this forming the type prefix, i.e. 30 IZ.

Operation

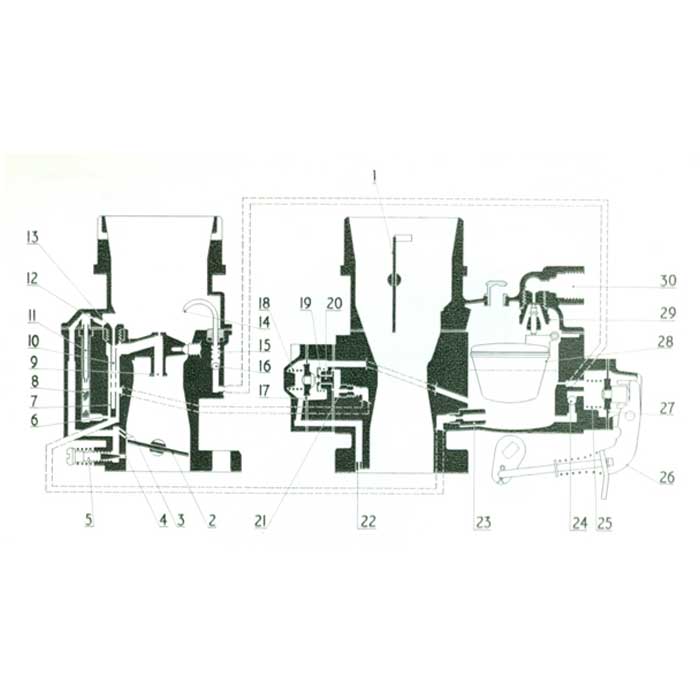

Fuel enters the carburettor through the inlet on the float chamber cover 30, passes through the needle valve 29, which controls the flow and then into the float chamber. As the petrol level rises, the float 28 which is of the lever-type completely moulded in plastic closes the needle valve when the correct level is attained. During engine operation, the level of fuel in the float chamber is controlled by the rise and fall of the float, closing or opening the needle valve, to cut off or admit fuel from the fuel pump, as required. The design of the mechanism ensures complete stability of the predetermined level, thus eliminating all need for routine checking. In the event of damage to the float however, this must be replaced immediately, to maintain correct fuel level.

Starting from Cold

The strangler is operated by a lever on the carburettor which is connected by a flexible cable to a dashboard control. To start from cold, it is necessary to pull the control fully out, thus closing the strangler flap I and at the same time, by means of an interconnecting rod, opening the throttle 2 a predetermined amount. The degree of throttle opening allows depression, created by the induction strokes, to reach the mixing chamber and choke tube areas and to ensure a fast-idling speed after starting. Switch on ignition (do not touch accelerator pedal) and operate the starter motor. Depression created by the induction strokes on rotating the engine causes a suitably proportioned mixture to be lifted from the main well 7 and discharged through the orifice 9 into the manifold. At the moment of the engine firing and running, a rise in depression, consequent upon the increase in engine revolutions, will automatically open the strangler a certain amount. This admits air for the dual purpose of weakening the mixture and together with the partly opened throttle 2, allowing the engine to develop a fast-idle speed to prevent stalling during the warming-up period. On driving the vehicle away, the progressive rise in engine temperature will require the dashboard control to be gradually pushed in toward the "off" position and this should be carried out in accordance with engine requirements. Once sufficient temperature has been reached, the dashboard control should be pushed fully in, as prolonged use of the system will cause unnecessary wastage of fuel.

Idling

When the throttle 2 is in the idling position, the mixture is supplied by (a) the slow-running tube 11, which obtains its fuel, filtered by the gauze 8, from the metered side of the main jet 23 through the restriction 6 and (b) the calibrated air bleed 12, in the air intake,

which provides air to partly emulsify the fuel. This mixture is then drawn down the vertical channel, to the idle discharge hole 4, which IS controlled by the volume screw 5. Adjustments are made to the Idling by the throttle stop screw and the volume screw. The throttle stop screw determines engine speed and rotating this clockwise. Or inwards, will increase the speed or turned in the reverse direction, will decrease the speed.

The quality of idling mixture is controlled by the sizes of slow-running tube II and air bleed 12. The former IS a variable but the latter is drilled in the carburetter casting itself and is not intended to be altered. Quantity of idling mixture is regulated by the volume screw 5. This is situated at the edge of the carburetter fixing flange, on the engine side of the throttle and has a conical tip which permits a greater or less amount of mixture to be inspired by the engine. This screw is turned inwards to reduce mixture supplied (weaken) and outwards to increase the amount of mixture supplied (richer).

Two small holes 3, close to the edge of the throttle, communicate with the idle circuit. Their function IS to aid the transfer of the fuel supply at small throttle openings and provide smooth progressive acceleration during these periods; they are therefore known as "progression" holes. They are not adjustable and apart from periodic cleaning, must not be tampered with.

Accelerating Pump

The purpose of this IS to prevent any hesitation in accelerating, that might otherwise occur, when a carburettor is adjusted to provide the leanest mixture at part-throttle cruising. To obtain economical running at such speeds, a controlled and metered supply of fuel is required when the throttle IS suddenly opened and this is supplied by the accelerating pump. When the pump diaphragm 27 is returned by spring 25, the pump chamber is charged with fuel, from the float chamber, through the non-return inlet valve 24. On depressing the accelerator, the movement of the actuating rod and lever 26 displaces the pump Diaphragm 27 which, in turn, forces fuel past the ball valve 16 and through the pump jet 14 into the airstream. The ball 16 prevents air entering the system, when the pump chamber is recharged by the action of spring 25 returning the diaphragm 27. Spring 15 retains the ball valve 16 to prevent loss. A further feature of this pump is the small back bleed drilling, that can be seen on the diagrammatic section, communicating between the back face of the pump chamber and the float chamber. The main purpose of this drilling IS to prevent fuel expansion, caused if the castings become very hot, giving rise to discharge from the pump jet.

In these conditions, excess fuel IS returned to the float chamber via the back-bleed drilling.

The Main Circuit

As the throttle continues to open, increased depression in the waist of the choke tube brings the main system into operation. Under this condition petrol flows from the float chamber, and IS metered by the main Jet 23 before passing into the main well 7, where it mixes with air metered by the air jet 13. The air enters the fuel stream by means of small cross holes drilled in the emulsion tube 10. From the main well, the mixture is fed into the main air stream through the main discharge Orifice 9 which is situated in the narrowest part of the choke tube. With Increase in engine speed, the fuel level in the main well 7 drops and uncovers the remaining holes in the emulsion tube 10. In this way, additional air enters the fuel stream and corrects the output from the main jet, according to engine speed and load.

Economy Device

On the main body to one Side of the float chamber, the economy device assembly IS attached by means of three brass screws. Under the cover of this assembly is a diaphragm and spring. This device is entirely automatic in operation and consists mainly of the spring 18 actuating a diaphragm 17, an economy Jet 21 and a spring-loaded valve 20, positioned in the assembly face. At cruising speeds, the relatively high induction manifold depression IS transmitted via a connecting channel to the chamber between diaphragm 17 and outer cover, thereby overcoming the pressure of spring 18 and moving diaphragm 17 to the left. This action allows the fuel chamber, between diaphragm and main body, to fill with fuel and the spring-loaded valve 20, to close. Since the jet 21 is then out of action, economical cruising is obtained on the flow from the main jet only.

As the throttle is opened, the depression present in the outer chamber is reduced, allowing the diaphragm spring 18 to expand. thereby forcing diaphragm 17 to the right. The spring-loaded valve IS thus moved off its seating and fuel, metered by jet 21, passes into the main well 7, augmenting the flow from the main jet and enriching the mixture for full throttle operation.

A calibrated restriction 22 is pressed into the depression transfer passage, from a milled groove In the face of the carburettor fixing flange. Apart from ensuring cleanliness from time to time, this part should not be tampered with.

Dismantling

To gain access to the various parts, first remove the air cleaner from the air Intake and fuel pipe from Inlet boss on float chamber cover. Disconnect throttle operating arm from throttle lever, remove strangler cable by releasing outer casing clip and slackening swivel in strangler lever. Pull off flexible pipe from vacuum advance tube protruding from carburettor fixing flange and finally undo the two nuts securing carburettor to induction manifold.

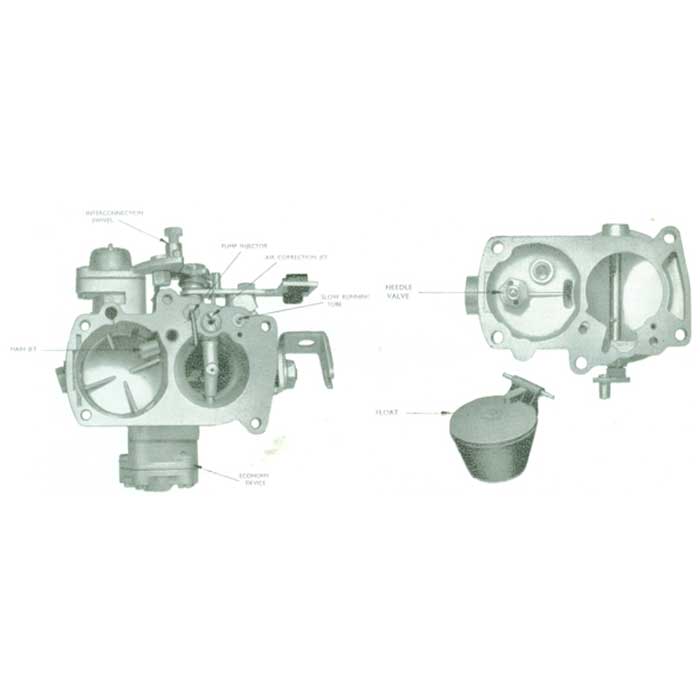

The float chamber cover and gasket are removed by unscrewing the five retaining screws which have captive spring washers. Inside the float chamber cover is the needle valve which controls entry of fuel to the carburettor. In the lower part can be seen the hook-shaped pump jet, which IS removed with its "0" ring seal by lifting out. Adjacent to this jet are the air correction jet, that has the emulsion tube attached and is unscrewed to remove and the slow-running tube, with gauze sheath, that can also be lifted out carefully.

Note: The casting which forms the main discharge assembly can be seen in the throat of the carburettor.

This is located by means of a grub screw which is locked In position on assembly. ON NO ACCOUNT TRY TO REMOVE OR LOOSEN

THIS SCREW.

To obtain access to the main jet, lift out the float and pivot pin. Undo the plug located at the base of the float chamber on the outside and through the aperture left by removal of the plug. Unscrew the main jet with suitable size and length of screwdriver.

Inspection of the pump diaphragm, spring and passages behind these can be effected by laying the Instrument on Its side with pump uppermost. Removing the four copper-plated fixing screws. While holding the cover in position then carefully swinging away the cover on the operating rod taking care to release the spring tension before final removal.

On re-assembly first position the spring In the main casting followed by the diaphragm which is fitted With spigotted centre Portion outwards (towards cover). When re-fitting cover see that the spring is correctly located in centre of diaphragm before inserting retaining screws.

To check economy device, remove the three brass retaining screws and lift off assembly and gasket. Behind the gasket is situated the economy jet which can be unscrewed with a Suitable screwdriver. Access to the economy spring and diaphragm can be gained by removing the two cadmium plated cover screws of the assembly that has been taken off the main casting holding the cover and carefully releasing spring tension before lifting off.

When replacing the diaphragm spring and cover, first locate the diaphragm on the body, place the spring In the cover and bring the two parts together with the spring located In the cup of the diaphragm. To refit the assembly locate the gasket, then position the assembly on the main body and replace the three fixing screws.

To re-fit the float chamber cover after all jets are replaced. fit float and pivot pin entering the float Into Its chamber first holding the protruding moulding then locate pivot pin In recess. Place float chamber gasket in position and holding the strangler cam lever in closed (full rich) position finally place on float chamber cover and re-fix with the five screws tightening evenly and securely from centre outwards.

Servicing

In any investigation of suspected faulty carburetion, first check through the instrument to ensure that the correct jet sizes, Recommended by the Manufacturers are fitted. Whilst It IS Important to see that jets have the right numbers stamped on them, the possibility that a jet may have been tampered with, or careless cleaning has altered the flow of petrol or air through a jet. Should not be overlooked. If therefore. there IS any indication that any of the jets have been interfered with a new part of the correct size should be fitted.

Although a general check of the carburetter is advisable, in the investigation of any complaint, we detail below, under specific headings, points that have a bearing on the particular trouble experienced. We cannot stress too strongly however that it is essential to ensure the electrical Side particularly Ignition setting contact breaker gaps and spark plug condition are all checked thoroughly and that the tappet adjustments are correct. All of these can upset the running

and are often wrongly diagnosed as "carburetter trouble".

Make sure there is petrol In the float chamber as cases are encountered where sediment or gum cause the needle valve to stick in the closed position, thus preventing the entry of fresh fuel when attempting to start. This can explain difficult starting as fuel in the float chamber may have evaporated after the vehicle has been standing for several hours. If a sticking needle valve is suspected remove the top half and operate the needle with a finger. Any tendency for the valve to remain closed can usually be overcome by rinsing it in mentholated spirit. This will dissolve gum deposit and wash of sediment. Ensure that the strangler flap in the air intake closes completely when the dashboard control IS operated. From examination of the choke control on the carburetter, it will be seen that there is no mechanical connection between the strangler control wire and the spindle on which the strangler flap is mounted.

Movement of a cam lever. on the side of the main body permits the spring-loading of the strangler spindle and arm to close the flap in the intake; therefore undue friction by reason of a bent spindle. Carboned-up bearings or a broken spring would explain inability to start through the strangler being in the partially or fully open position when the dashboard control is fully extended. Removal of the air cleaner will enable this to be checked. Excessive tightening of the air cleaner connection could distort the air Intake and cause the strangler flap to stick open. The Intake IS not fragile and the above will only occur if excessive force is used in tightening the connection.

The only adjustment that affects starting from cold is the amount the throttle is opened above the normal Idling position when the strangler is closed. This is affected by means of a link between throttle and strangler and known as the Interconnection adjustment.

The setting for a particular engine includes the amount the throttle is opened when the strangler is shut. The measurement given is the gap between the edge of the throttle and the wall of the throttle bore (on the slow-running outlet side) but whenever possible, is also translated into HALF-turns of the throttle stop screw, from the point at which the screw commences to open the throttle from the dead-shut position.

Difficult Starting when Engine is Hot

First check that the needle valve is of the correct size. Having cleaned the assembly, replace it with the correct washer and ensure it is screwed tightly in position. Examine the float for damage and see that it moves freely on the pivot pin. A new needle valve of the size specified will eliminate the possibility of the assembly being worn and no longer able to withstand Normal fuel pump pressure.

Where it is found that petrol floods into the manifold from the discharge orifice within seconds of switching off the motor, in spite of fitting a new needle valve, check the fuel pump pressure and if necessary have it reduced to prevent the internal flooding which could explain difficulty in hot starting. An additional washer under the needle valve may be effective in preventing flooding and could be tried before recourse to lowering pump pressure.

Generally one can start the motor by gently opening the throttle to the fully or near-fully open position, then rotating the engine by the starter to clear the over-rich condition.

Erratic Slow-running or Stalling on Deceleration

Make certain the slow-running jet is clean, also ensure that the feed hole to the channel in which the jet screws is free. The best method of checking this is to remove the slow-running tube and main jet then insert the nozzle of a syringe filled with petrol into the hole from which the slow-running tube has been removed; on operating the syringe, petrol should flow out of the hole from which the main jet has been extracted.

It is also necessary to ensure that the slow-running air bleed, into the air intake is clear. Check to make certain that the slow-running outlet hole and the progression hole or holes in the throttle barrel are clear and not carboned-up to restrict the orifice. Remove the volume control screw to make sure the tapered end is in good condition. If it has been screwed down hard into the slow-running hole several times, a parallel portion will have been formed on the taper; this will render abortive any attempt to adjust the screw, which should be replaced with a new one. Make certain the spring under the head of the screw effectively spring-loads the screw. to prevent it vibrating out of position when set.

The degree of throttle opening will determine the speed of slow-running. while the adjustment of the volume control screw will vary the mixture strength. Set the former to give a reasonable idling speed, then adjust the volume control screw so that, at the speed as set by the throttle stop screw, the engine will idle evenly, with no tendency to stall on snap closure of the throttle. Also make certain that, as the throttle is opened slowly from the idle position onto the progression holes, there is clean progressive acceleration of the speed of the engine.

Check carburetter fixing flange for distortion and see that the gasket between this and the induction manifold is sound, to eliminate possibility of air leakage at this point. In time, wear of throttle spindle and the bearings in which it operates will cause difficulty in obtaining satisfactory idling and explain hesitation and flat spots in opening-up off idle on to the main carburetter. Stalling of the engine is usually due to the idle speed being set too slow, or the mixture too lean by reason of incorrect adjustment. It is essential that the foregoing adjustments are made when the engine is at normal working temperature. While the motor is cool during the warming-up period. Extension of the choke control will provide the wider throttle opening that will be necessary to prevent the motor stalling.

Excessive Fuel Consumption

Having checked to ensure the carburetter has the standard setting of jets and air bleeds fitted, make certain that all holes and passages in the instrument are clear. See that the strangler flap in the air intake opens completely when the dash control is released. If a replacement diaphragm is needed it is always best to fit a new spring, as the tension of the spring is vital to the correct operation of the economy diaphragm.

When re-assembling the economy diaphragm, see that the valve is clean and moving freely and that the spring beneath the cover is in position and located squarely in the recess of the metal cup in the centre of the diaphragm. Take care to tighten evenly and fully the screws which secure both the assembly and the cover. Any leakage at the joint will affect the degree of depression necessary to overcome the spring tension which normally holds the diaphragm in the open position.

Carry out similar check of pump diaphragm and when assembling, see that the diaphragm is fitted with the plain spigot towards the outside. If there are symptoms of richness on idling and adjustment of the volume control screw fails to rectify, this would point to internal flooding, the needle not closing on its seating by reason of dirt, wear or excessive pressure from the fuel pump.

Clean the needle valve, ensure it is fitted with the correct washer and screwed tightly in position. Make certain the float chamber gasket is in good condition. Ensure the float moves freely on the axle pin. A new needle valve, of the size specified for the particular application, with a new washer, should be fitted if the needle shows signs of appreciable wear. (Approximately 15,000 miles).

Should it be found that after the above attention the obvious richness persists, the explanation is doubtless excessive fuel pump pressure and this should be checked and lowered. A loose float chamber plug or damaged aluminium. Washer beneath this will cause leakage, with consequent heavier consumption.

Poor Acceleration

Check that the pump diaphragm is sound and is returned to the charged position by the spring incorporated in the assembly. Remove the pump jet to ensure it is perfectly clear to give an unbroken stream of petrol from the orifice when the pump is operated and that the rubber "0" ring, sealing the jet, is sound. Flat spots or hesitation on progressive opening can generally be eliminated by careful adjustment of the slow-running mixture, after making certain the progression holes in the throttle barrel are clear. In time, wear of the carburetter will affect acceleration and slow-running adversely.

Loss of Power

Check jet and needle valve sizes, make certain that all jets and passages are clear and that the throttle is opening fully. In cases where an engine has been modified, with a view to increasing power output and we are advised of modifications made, we can usually suggest an alternative setting which will serve as a basis for commencing tests to tune the carburetter to suit the altered or modified engine. These remarks apply equally to conversions to twin or multiple carburetters and we shall be pleased to pass on to owners the benefit of our experience on similar installations.

In dismantling the carburetter for cleaning and checking jets etc., it is advisable to have available a set of new gaskets. There is a Gasket Pack containing all washers and gaskets, in kit form, to suit the particular model on your car. Insist on the genuine Zenith Pack-nothing else is as good.