This Stromberg •• CD •• or constant depression instrument is different from previous carburetters we have manufactured of fixed choke tube design. It operates on the" constant vacuum" principle, the choke area and the jet orifice varying according to the degree of throttle opening and the speed of the engine which will alter according to the load. It is a simple, compact and dustproof instrument with concentric float chamber surrounding the jet orifice with its attendant advantages over the more orthodox out-rigged float chamber some distance away from the jet.

Three principal die-cast aluminium castings are used in the construction, the main body, suction chamber cover and the float chamber, resulting in an extremely light-weight carburettor relative to bore size and air flow.

The CD carburettor is suitable for installation between horizontal and semi-downdraught, the features which permit this inclination are the concentric float chamber and a central jet orifice which gives a very steep flooding angle, ensuring good operation and stable idling in hilly terrain with no tendency to cut out on fast cornering. The carburettor has a cold start device interconnected with the throttle to provide for a specific degree of throttle opening to ensure a suitable fast-idle as necessary when the motor is cold.

PRINCIPLE OF OPERATION

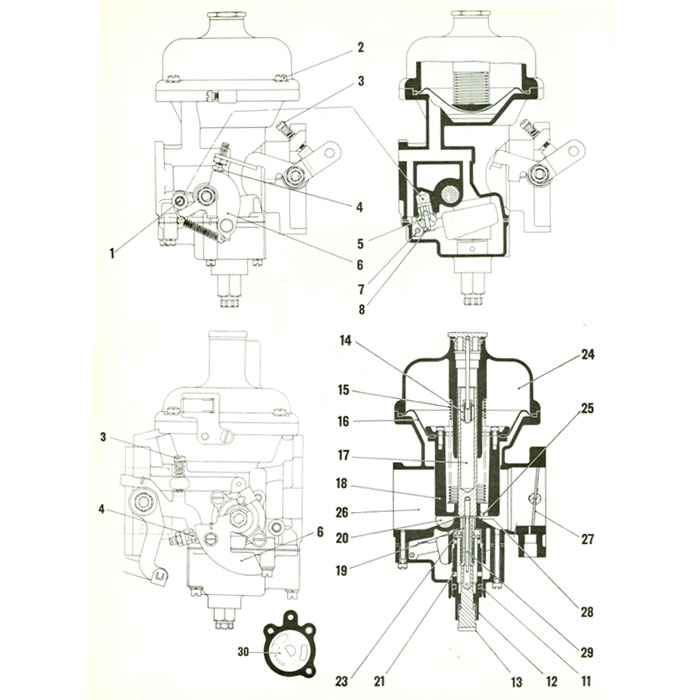

The petrol inlet I, a parallel tube to accommodate a flexible fuel pipe is at the side of the main body. From here fuel passes into the float chamber via the needle seating S where the flow is controlled by the needle 8 and the twin floats on a common arm 7. As the petrol level rises the float lifts and, by means of the float arm and tag, closes the needle on its seating when the correct level has been attained. With the engine running, petrol is drawn from the float chamber, the float descends and more fuel is then admitted through the needle seating. In this manner, the correct level is automatically maintained the whole of the time the carburetter is in action. The fuel from the float chamber will rise in the jet orifice 19 via hole 21 in the jet assembly, the fuel in the jet orifice being maintained at the same level as that in the float chamber.

Starting from Cold

Carburetter types 125 CD, 150 CD, 175 CD and 175 CD·1.

When the choke control on the instrument panel is pulled out It operates the lever 6 at the side of the carburetter; this rotates the starter bar 20 to lift the air valve 18 in which is fitted the metering needle 29 from the jet orifice 19 to increase the area of the annulus between needle and orifice. In this manner the enriched mixture necessary to ensure cold starting is provided. Simultaneously, the cam on the lever 6 will open the throttle beyond the normal idle position according to the setting of the fast-idle stop screw 4 to provide the fast-idle speed when the motor is cold. When the motor fires the increased depression will lift the air valve 18 to weaken the initial starting mixture and prevent the engine stalling through over richness. While the choke remains in action the car may be driven away but the control knob should be released or pushed in gradually as the engine attains normal working temperature.

It will be appreciated that movement of the choke lever 6 will decrease progressively the extent of enrichment and degree of throttle opening for fast-idle to the point where the screw 4 is out of contact with the cam on the choke lever and the throttle is permitted to return to the normal idle position as determined by the setting of the throttle stop screw 3.

Carburetter types 125 COS, 150 COS and 175 CD·2S.

When the choke control on the instrument panel is pulled out, it operates lever 6 at the side of the carburetter; this rotates a disc 30 in the starting device in which a series of holes of different diameters are drilled. In the full rich position the largest hole will be in communication with the starter circuit and provide the richest mixture.

Petrol is drawn from the float chamber via a vertical drilling adjacent to the central main feed channels, through the starting device and into the throttle body on the atmospheric side of the throttle plate. Simultaneously, the cam on the starter lever will open the throttle beyond the normal idle position, according to the setting of the fast-idle stop screw 4, to provide the fast-idle speed when the motor is cold.

As the dash-board control on the instrument panel is gradually released, smaller holes will provide the petrol feed from the float chamber, therebyprogressively weakening the mixture strength to the point where the control is pushed fully home and mixture strength will be governed by the setting of the orifice adjusting screw and the idle speed determined by the setting of the throttle stop screw. On certain twin carburetter installations, the starting device is fitted to one unit only, and connected to the other by means of a plastic tube, providing a suitable mixture via a duplicated set of holes drilled in the starter disc 30.

Note: The accelerator pedal should not be depressed when starting from cold on either type.

Idling

There is no separate idling circuit in the Stromberg .. CD" carburettor, and the fuel is provided by the jet orifice 19, the amount being controlled by the setting of the orifice adjusting screw 13 and the speed of idle by adjustment to the throttle stop screw 3 which limits the closure of the throttle when the foot is off the accelerator pedal. Turning the orifice adjusting screw, when looking on this clockwise decreases the mixture strength; anti-clockwise will enrich.

Normal Running

With the opening of the butterfly throttle manifold depression is transferred (via a drilling 25 in the air valve) to the chamber 24 which is sealed from the main body by the diaphragm 16.

The pressure difference between chamber 24 and that existing in the bore 26 causes the air valve to lift, thus any increase in engine speed or load will enlarge the effective choke area since the air valve lift is proportional to the weight of air passing the throttle 27. By this means air velocity and pressure drop across the jet orifice remain approximately constant ensuring good fuel atomisation at all speeds.

As the air valve 18 rises it withdraws a tapered metering needle 29 held in the base of the air valve by a screw from the jet

orifice 19 so that fuel flow is increased relative to the greater air flow. The metering needle is a variable and is machined to very close limits to provide a mixture ratio for all speeds and loads in line with engine requirements as determined by exhaustive tests on bench and road by carburetter specialists working in collaboration with the engine manufacturers.

orifice 19 so that fuel flow is increased relative to the greater air flow. The metering needle is a variable and is machined to very close limits to provide a mixture ratio for all speeds and loads in line with engine requirements as determined by exhaustive tests on bench and road by carburetter specialists working in collaboration with the engine manufacturers.

Acceleration

At any point in the throttle range a temporarily richer mixture is needed at the moment the throttle is suddenly opened. To provide this, a dash pot or hydraulic damper is arranged inside the hollow guide rod 17 of the air valve.

The rod itself is filled with suitable oil to within a iN of the end of the rod in which the damper 14 operates. When the throttle is opened, the immediate upward motion of the air valve is resisted by this plunger. For that short time the suction or depression at the jet orifice is increased and the mixture is enriched. For all normal requirements engine oil SAE 20 is suitable unless the car manufacturers recommend some variation from this.

The downward movement of the air valve 18 is assisted by the coil spring 15 and/or a weighted air valve.

The downward movement of the air valve 18 is assisted by the coil spring 15 and/or a weighted air valve.

ADJUSTMENTS

Setting the Idle

Two adjustments are employed when regulating the idle speed and mixture, and the following procedure should be adopted in setting the throttle stop screw 3 which controls the speed, and jet adjusting screw 13 which determines the quality of air-fuel mixture entering

the cylinders.

the cylinders.

Remove the air cleaner and damper and hold the air valve 18 down on to the bridge 28 in the throttle bore. Now screw up the jet adjustment screw 13 (a coin is ideal for this purpose) until the jet is felt to come into contact with the underside of the air valve. From this position turn down the jet adjusting screw three turns. This establishes an approximate jet position from which to work. Run the engine until it is thoroughly warm, and obtain by means of the stop screw 3 an idle speed of some 600/650 r.p.m. The idle mixture will be correct when the engine beat is smooth and regular, and by careful and gradual adjustment of the jet adjustment screw 13 the correct position will be determined.

As a check, lift the air valve a very small amount (1/32 of an inch) with a long thin screw-driver and listen to the effect on the engine. If the engine speed rises appreciably, the mixture is too rich and, conversely, if the engine stops, the mixture is too weak. Properly adjusted, the engine speed will either remain constant or fall slightly on lifting the air valve.

Adjusting and Synchronising Twin Carburetter Installation.

Loosen the clamping bolts on the throttle spindle couplings between the two instruments. Next, unscrew the throttle stop screws to permit the throttles in each carburetter to close completely, and then screw in the throttle stop screws 3, to the point where the ends of the screws are just contacting the castings. From this point, rotate the stop screws It complete turns each, to open the throttles an equal amount and provide a basis from which final speed of idle can be set.

Note: Ensure fast-idle screw is clear of cam, otherwise incorrect synchronising will result.

Regulate the jet adjusting screws 13 as detailed under the heading" Setting the Idle" i.e. three turns down from the point where the jet orifice comes into contact with the base of the air valve 18. Check that both cold start levers are fully off against the stops with dashboard control pushed in. Adjust coupling and control wire as necessary.

Start engine and warm-up to normal running temperature. Check synchronising of throttles with suitable instrument, or .. tube to ear" method, at each intake, then tighten clamping bolts on throttle coupling. Set the throttle stop screws to give required idle speed, turning each screw an equal amount. Make final mixture adjustment with jet adjusting screws, turning each a similar amount, until idling is even as previously detailed.

If care is exercised in setting each throttle open the same extent, then lifting each air valve in turn will give similar re-action as outlined under the instruction" Setting the Idle" and any final setting of the jet adjusting screw can be made to ensure idle speed remains constant or falls slightly on lifting the valve.

Finally, adjust fast-idle stop screw in accordance with setting details for the particular application and lock securely with lock nut.

Note: Remember that the idle quality depends to a large extent upon the general engine condition and such points as tappet adjustment, spark plugs and ignition timing should be inspected if idling is not stable. It is also important to eliminate any leaks at manifold joints. There will come a time when the wear of throttle spindle and bearings in the carburettor will effect idle and it will be advisable to replace the spindle. Later, when a new spindle is not effective by reason of the degree of wear in bearings in the unit it will be necessary to fit a new carburettor.

Float Level

When correctly set and with the carburetter inverted measure to the highest point of the floats above the face of the main body with the fuel inlet needle on its seating. The correct measurement is indicated on our Parts Schedule for the appropriate application. Great care must be taken not to twist or distort the float arms, to ensure a constant fuel level. Should it be necessary to reset the float level, this can be carried out by bending the tag which contacts the end of the needle 8. Care should be taken to maintain the tag at right angles to the needle in the closed position.

Note: An additional washer under the needle seating assembly will lower the level and is a simpler method of effecting a small change than bending the tag on the float.

Jet Centralisation

The efficient operation of the carburetter depends on free movement of the air valve and needle in the jet orifice. In the Stromberg there is annular clearance around the orifice bush 23 which permits the lateral positioning of the bush and jet. Thus it may be clamped up in such a position that the metering needle 29 moves freely in the orifice 19. When the carburetter leaves the factory the orifice bush is in the correct position and this can be checked by lifting the air valve by means of the spring loaded pin and noting that the valve falls freely. If for any reason, the jet assembly is removed, it must be re-centred.

Procedure

- Lift the air valve 18 and tighten the jet assembly 12 fully.

- Screw up the orifice adjuster until the top of the orifice 19 is just above the bridge 28.

- Slacken off the whole jet assembly 12 approximately half-a-turn to release the orifice bush 23.

- Allow the air valve 18 to fall; the needle will then enter the orifice and thus automatically centralise it. If necessary, assist the airvalve drop by inserting a soft metal rod in the dashpot after unscrewing the damper.

- Tighten the assembly 12 slowly, checking frequently that the needle remains free in the orifice. Check by raising the air valve approximately ¼ of an inch and allowing it to fall freely. The piston should then stop firmly on the bridge.

- Reset idle as outlined earlier.

Sticking of the air valve can be explained by dirt or carbon on the outside diameter of the air valve and the bore in which the air valve moves or if the metering needle is bent. To remove the air valve assembly take off the top cover by undoing the screws 2 when the assembly with diaphragm can be lifted out of the main body. The outside of the air valve and the bore can be wiped clean with a rag that is moistened with paraffin or petrol but if the diaphragm has expanded one will have to allow it to dry for a few minutes before it will fit on the bead and recess for the locating tab. If it is necessary to clean the diaphragm, use only clean rag. In common with other products made from rubber compounds any contact of the diaphragm with volatile cleaners such as tri-chloroethylene should be avoided. If examination of the needle indicates it is bent it should be replaced with a new one bearing the specified marking as detailed in the specification for the particular make and model of engine. In replacing or fitting a new metering needle the shoulder must line up with the lower face of the air valve and the locking screw tightened fully.

The needle is machined to very close limits and should be handled with care.

Air Valve/Diaphragm Assembly

A bead and locating tab is moulded to both the inner and outer radii of the diaphragm to ensure correct positioning of this item. The diaphragm is secured to the air valve by a ring and screws with lock washers and it is very necessary to ensure the bead is correctly located and the screws tightened fully. Location for the bead and tab on the outer radius of the diaphragm is provided by a location channel at the top of the main body. It is important that location beads and tabs are accurately positioned. When refitting the suction chamber cover, place it accurately so that the screw holes line up with those in the main body, this will prevent any disturbance of the located diaphragm.

Air Valve Rod and Guide

The air valve rod and guide must be kept clean and should not be handled unduly to avoid corrosion. A few drops of light oil should be applied to the rod before refitting.

Float chamber Removal

To prevent the leakage of petrol from the f1oatchamber, a rubber" 0 •• ring II is situated between the jet assembly and the float chamber spigot boss.

Care should be taken when removing the float chamber to avoid damage to the faces and floats.

A CARBURETTER IS AN ACCURATE AND DELICATE INSTRUMENT, IT WILL ONLY GIVE OF ITS BEST IF TREATED AS SUCH