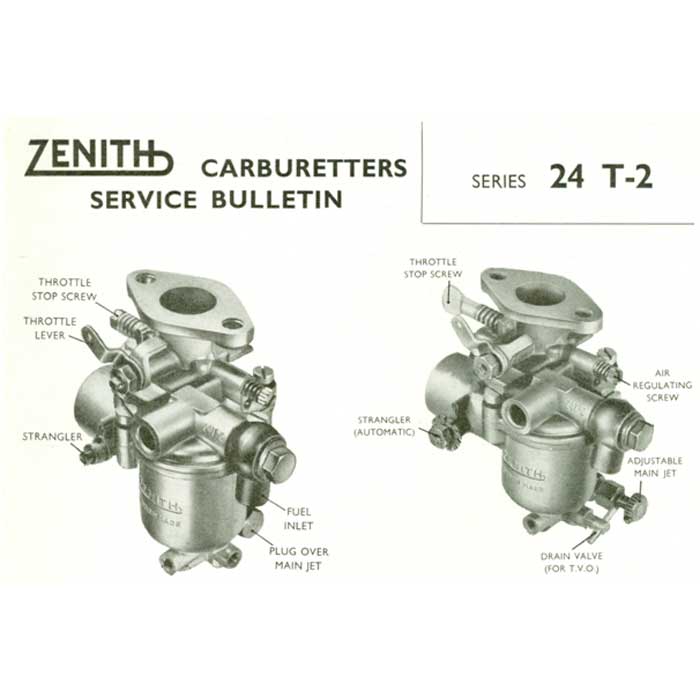

The 24 T -2 carburetter is an up draught type of compact design, developed principally for use on agricultural equipment, marine engines, industrial power units and light commercial vehicles. It can be supplied in several versions, the main variations being the method of controlling the throttle and the air strangler, the type of strangler fitted (automatic or non-automatic) and the incorporation of an adjustable, instead of a fixed, main jet. The float chamber is arranged as close as possible to the main discharge tube, so that a steep flooding angle in all directions is assured. The carburetter consists of two units, the principal portions of which are die castings. The upper part, or throttle body, includes the fixing flange which bolts directly to the engine induction manifold; the lower consists of the float chamber and air intake. They are secured to each other by five screws 7. The choke tube is a removable component, and a range of sizes is available. The diameter of the throttle bore outlet at the fixing flange is 24 mm. (0·945"). A variety of fuels can be used: these include petrol, paraffin and tractor vaporizing oil.

Operation

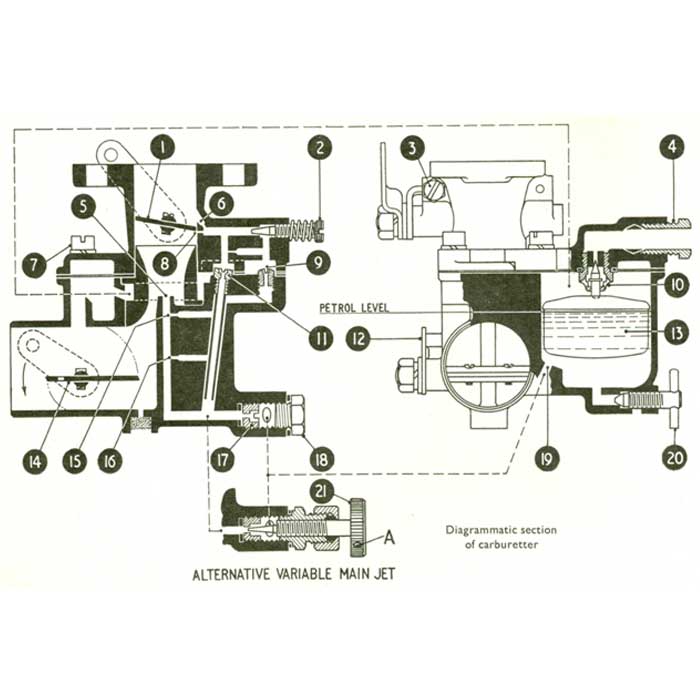

Fuel enters the carburetter through the inlet 4 in the throttle body, and then passes into the float chamber via the needle and seating 10, which controls the flow. As the level raises the float lifts, and the needle, being in contact with the float, cuts off further entry of fuel when the pre-determined level is reached. While the engine is running, fuel is drawn from the float chamber, the float then descends and more fuel is admitted. This sequence is entirely automatic, and continues all the time the carburetter is in action, thus constantly maintaining the correct fuel level. From the float chamber, fuel flows into the horizontal main jet chamber through the short inclined passage 19. On passing through the main jet 17, it is drawn through a vertical discharge nozzle, the tip 5 of which is located in the waist of the choke tube, i.e in the region of maximum depression.

STARTING FROM COLD

Non-automatic stranglers

A rich mixture is required for starting an engine in a cold condition. To provide this, a strangler is fitted in the carburetter air intake. When the control on the instrument panel is operated, the strangler flap closes; consequently, when the engine is turned over the resulting depression is concentrated entirely upon the jets, and a very rich mixture is provided. With non-automatic stranglers it is usually necessary to open the flap slightly as soon as the engine fires, to admit extra air, otherwise difficulty may be experienced with stalling. Alternatively, the throttle should be opened slightly by means of a hand control; the required degree will soon be found by experiment.

Automatic stranglers

With this system, the strangler flap is mounted on a spindle offset to the centreline of the air intake. It is closed by the panel control, as before, but in this case the flap is lightly loaded by a small coil spring, which tends to keep it in the closed position. When the engine starts, the high depression created overcomes the tension of the spring, permitting the flap to open sufficiently to admit the extra air necessary for weakening the mixture. Most 24 T -2 applications have an automatic strangler system, with an interconnection rod which provides a link between the strangler and throttle. With this arrangement, when the strangler flap is closed the throttle opens the correct amount to give a good fast-idle.

ALTERNATIVE VARIABLE MAIN JET

Idling

Alternative types of idling circuits are employed in the 24 T-2 series; in these the slow-running tube can be either vertical or inclined. The object of the latter (shown in the diagram) is to provide a longer feed. Fuel is drawn direct from the main jet discharge channel, and, the end of the tube being below the emulsion holes, the slow-running system is in action for a longer period (a feature found necessary on certain designs of engines) thus providing a cleaner and smoother pick-up. When the throttle is almost closed, the slow-running mixture is supplied by the slow-running jet 11, which draws its fuel from the metered side of the main jet 17 at the base of the float chamber. This fuel is partly emulsified by air from an air-bleed hole (the small horizontal hole shown just above the head of the slow-running jet) in communication with the air jet, and also by air admitted by the conical tip of the air regulating screw 2. The resulting mixture is drawn through the inclined outlet hole 6, and the mixture strength is controlled by the position of this screw. Idling adjustments are made by the throttle stop screw and air regulating screw 3 and 2 respectively. Turning the former clockwise will open the throttle and increase the engine speed. When it is unscrewed, the engine speed will be reduced.The quality of the idle mixture is controlled by the setting of the air regulating screw, and the size of the small horizontal bleed hole to which reference has already been made. The latter is not adjustable, as it is a permanent drilling in the die casting. Should the engine refuse to tick-over for any length of time, the slow-running jet may be obstructed, and should be cleaned. After replacement, reset the idling with the air regulating screw and the throttle stop screw. If the engine "hunts" the mixture is too rich, and is weakened by turning the air regulating screw in an anti-clockwise direction. Conversely, to enrich the mixture the screw must be turned clockwise.

The hole (or in some cases holes) 8 at the throttle edge communicates with the idling circuit. This aids the changeover from the idling to the main jet system, and gives a smooth progressive transfer; it is therefore called the progression hole. Being a drilling in the die casting, it is not intended that it should be interfered with in any way. As the throttle continues to open, the engine depression at the discharge nozzle tip 5 will draw fuel direct from the main jet.

The slow-running system is now no longer operating, and the fuel level in the inclined passage for the slow-running tube will have fallen; the emulsion holes 15 and 16 will therefore be in direct air communication with the main discharge nozzle. The extent of the air bleeding depends on these holes, and upon the size of the air jet 9. The partly-emulsified mixture passes into the waist of the choke tube, where it is still further atomized by the airstream through the carburetter.

Main jet

Either an adjustable or a fixed main jet (21 and 17 respectively) can be supplied. When an adjustable jet is used, the setting is carried out by the engine manufacturer and should not be altered without good reason. (The small button "A" in the head of the adjusting needle is provided merely as a means of registering the position of the needle.)Always regulate the screw with the engine at normal running temperature and working load, with the throttle wide open.To richen the mixture, the adjusting screw 21 should be turned anti-clockwise.

By screwing it clockwise. the mixture will be weakened. Lack of power, engine overheating and cutting-out will be experienced if the mixture is too weak. Maximum fuel economy is obtained by setting the mixture for full power. Too rich a mixture will result in rapid carbon formation in the combustion spaces, a dirty exhaust and possible poor starting due

to fouled spark plug gaps.

NOTE: When resetting the adjusting needle, do not force the taper on the jet seating as this will damage the conical tip. and result in difficulty in obtaining a correct setting.

Drain tap

Where paraffin or T.V.O. is used, a drain tap 20 is fitted under the float chamber. After use, ensure that it is screwed home firmly.Float chamber ventilation

The float chamber is vented either to the atmosphere or to the air intake, depending upon the particular application. External ventilation is achieved by a hole in the float chamber cover which breaks into the unused petrol-inlet boss. It IS essential that this hole is kept unobstructed. For inside ventilation, an opening in the air intake admits air to the float chamber via a curved channel in the casting. The air for slow-running is supplied by an annulus round the choke tube.

Choke tube

The size will determine the weight of charge inspired by the engine; that usually decided upon is the smallest that will enable the engine to develop the maximum power required for a particular application.

Main jet

For all speeds above idling, the main jet 17 or 21 alone supplies the mixture.

Air jet

The air jet 9 screws into the upper face of the float chamber, adjacent to the slow-running jet. Increasing its size will weaken the mixture by reducing the depression on the main jet. Altering the size of the jet will affect the mixture strength at all engine speeds, but particularly those in the higher ranges, when

the depression in the choke tube is at its maximum. In some instances, where the full value of the drilled hole is required for the ventilation of the main jet, an air jet is not used.

Slow-running jet

The name is self-explanatory, the purpose of the jet being to supply metered fuel to the edge of the throttle plate for idling, and to the progression hole or holes 8. Half-size jets are not available, as the air regulating screw has sufficient range of mixture control to suit individual engines.

Throttle/strangler interconnection

This enables the degree of throttle opening for cold starting to be varied between certain limits. The setting is adjusted by releasing the pinching screw in the strangler lever swivel, moving the tube up or down asrequired, and re-clamping.

Petrol level

With the float chamber in position, and the float holding the needle shut against its seating, the petrol level should be 15 mm. (W') below the top face of the float chamber at 4' -6" head. The level may be lowered, if required, by substituting a thicker washer under the needle seating. The normal thickness is I mm but washers -h" or 2 mm, thick can be supplied.

Needle valves and seating’s

These parts are calibrated in mm. the size being stamped on one of the flats of the hexagon. This size is dependent upon the fuel delivery pressure, and the capacity and power of the engine.

General

Unless otherwise stated, all the jets and air bleeds in this carburetter are calibrated in units of hundredths of a millimetre. Main and slow-running jets are normally available in steps of five units. Air jets are usually supplied in the following sizes: 100, 120, 150, 175, 200,250 & 300. In all cases, a higher number indicates a larger calibration, and therefore a jet stamped 95 is larger than one marked 90. Half-size main air jets can be supplied to order for final tuning, one stamped 97 being midway between 95 and 100. Choke tubes have their sizes marked inside, the number indicating the smallest diameter of the bore in millimetres. Variations are in steps of one millimetre, from 12 mm, to 20 mm. (inclusive) and half-sizes are not available.

In addition to the above-mentioned jets and air bleeds which could, if necessary, be altered after the carburetter is in general service, there are several drillings in the carburetter which can be varied during manufacture, i.e., the size of the progression hole(s), the number and size of emulsion holes, etc. These drillings are a means of tuning a carburetter to suit all load and speed conditions of the engine. It should be understood, however, that once the sizes of the variables have been decided, the mixture strength at all loads and speeds will be constant, provided that all jets, passages and holes are quite clean and the carburetter is mechanically sound. When investigating faulty carburetion, it is always advisable first to check that the setting, including the choke tube size, corresponds to that advised for the application concerned.

Although the jets may have the correct sizes stamped on them, the possibility that they may have been tampered with should not be overlooked. Where this is suspected, it is strongly recommended that new replacement parts of the correct size be fitted. A general check is always advisable when carburation is being investigated, and we give below advice covering the more usual complaints encountered in general service. It must be appreciated that, after years of service, the moving parts in the carburetter will inevitably wear. If the vehicle is some years old, and the carburetter is the one originally fitted, this wear-which can affect all aspects of carburation-can have a considerable bearing on some of the typical troubles mentioned below. We therefore strongly recommend that, when an engine needs a major overhaul, the worn carburetter is replaced by a new unit, so that the utmost benefit may be obtained when the engine is restored to its original condition.

In addition to the above-mentioned jets and air bleeds which could, if necessary, be altered after the carburetter is in general service, there are several drillings in the carburetter which can be varied during manufacture, i.e., the size of the progression hole(s), the number and size of emulsion holes, etc. These drillings are a means of tuning a carburetter to suit all load and speed conditions of the engine. It should be understood, however, that once the sizes of the variables have been decided, the mixture strength at all loads and speeds will be constant, provided that all jets, passages and holes are quite clean and the carburetter is mechanically sound. When investigating faulty carburetion, it is always advisable first to check that the setting, including the choke tube size, corresponds to that advised for the application concerned.

Although the jets may have the correct sizes stamped on them, the possibility that they may have been tampered with should not be overlooked. Where this is suspected, it is strongly recommended that new replacement parts of the correct size be fitted. A general check is always advisable when carburation is being investigated, and we give below advice covering the more usual complaints encountered in general service. It must be appreciated that, after years of service, the moving parts in the carburetter will inevitably wear. If the vehicle is some years old, and the carburetter is the one originally fitted, this wear-which can affect all aspects of carburation-can have a considerable bearing on some of the typical troubles mentioned below. We therefore strongly recommend that, when an engine needs a major overhaul, the worn carburetter is replaced by a new unit, so that the utmost benefit may be obtained when the engine is restored to its original condition.

Difficult starting from cold

First ensure there is petrol in the float chamber and that fuel is forthcoming by operating the fuel pump hand primer, or by turning on the fuel tap where a gravity feed system is employed. It is not unusual to find the needle is sticking on its seating due to gum deposit or sediment in the fuel. Where this condition

is suspected, the assembly should be removed and rinsed thoroughly in mentholated spirit to ensure freedom of movement. The strangler flap in the air intake should close fully when the instrument panel control is operated. If an automatic flap is fitted, remove the air cleaner and open the flap with finger pressure, which should then return smartly by the action of the light coil spring. It is necessary to carry out the above check as, on examination of the strangler parts, it will be seen there is no positive connection from the strangler spindle to the panel control knob. Excessive friction will result if carbon forms on the spindle or in the bearing bosses, thus overcoming the spring action; even though the panel control behaves normally, the flap will remain open. The interconnection link should ensure that the throttle is opened beyond the normal idling position when the strangler flap is closed. If this is in order, and the engine is still reluctant to start, a small increase in the degree of throttle opening will usually prove effective. With a direct action strangler, the degree of throttle opening should be altered.

Difficult starting when hot

This can be due to internal flooding, which will be noticed by petrol dripping from the porous plug under the air intake. It may be caused by excessive engine vibration, dirt in the needle seating, a punctured float or a badly-worn needle and seating. If either of the latter are suspected, a new unit should be fitted. Should flooding persist after a new needle valve has been installed, the fuel pressure should be checked, and remedied if necessary. (The new Zenith DA-3 fuel filter, specially designed to fit directly into the fuel inlet connection of this carburetter, is recommended to prevent the entry of foreign matter. Particulars will be supplied on application). Air leaks at the carburetter or induction manifold flanges can also give rise to poor starting. Check the carburetter flange nuts and manifold nuts for tightness. If necessary, fit new gaskets. Should the carburetter flange not be flat, true it carefully with a file. When a rich condition exists, turning the engine over with the throttle and strangler open and the air cleaner disconnected will help to clear the engine cylinders and ensure a ready start.

Erratic slow-running. or stalling on deceleration

Remove and clean the slow-running jet 11, also check the outlet hole 6 and progression hole 8 in the throttle body. Any carbon formation should be carefully removed, but avoid the use of a sharply-pointed instrument which may enlarge the diameters. To check whether the slow-running jet well is free from obstruction, remove the main jet plug 18 or adjustable jet assembly 21, And insert the nozzle of a syringe filled with clean petrol into the hole from which the jet II has been removed. On discharging the Syringe, petrol should flow through the drilling from which the main jet was removed. When replacing jets use a screwdriver of correct size, to prevent damaged slots and threads caused by a badly-fitting blade. Jets should be screwed home firmly, as leakage may take place down the thread and affect the slow-running. If the air-regulating screw has been screwed home hard several times in the process of adjustments, a parallel portion will be formed on the conical tip.

This will adversely affect the range of the screw, and a new one should be fitted. Ensure that the spring effectively spring-loads the screw, and prevents it vibrating out of position. The adjustment of the air-regulating screw will determine the mixture strength, while the degree of throttle opening will vary the engine r.p.m. Set the throttle stop screw to give a reasonable speed; 500/600 r.p.m. is acceptable. Then adjust the air regulating screw to give good idling, with neither a tendency to stall on sudden deceleration nor for the engine to "hunt". Also ensure that a gradual opening of the throttle from the idling position to the progression holes and on to full throttle gives smooth, progressive engine acceleration. Having set the mixture strength it may be found necessary to readjust the throttle stop screw slightly to give a reasonable engine idle speed. Stalling is usually the result of the mixture being too weak, or the idle speed too low. It is essential that the slow-running adjustment be carried out with the engine at its normal working temperature.

Loss of power

All jets and drillings should be clean, and the throttle free to open fully. Where an adjustable main jet is used, check that the adjustment has been carried out correctly. If a fixed jet is used, after having checked all the usual points a larger main jet may be tried. When ordering jets, give details of the engine, together with the identification marks stamped on the carburetter inlet boss, so that the correct parts can be supplied.

Changeover of fuel

With T.V.O. applications, the engine manufacturer's instructions concerning the changeover from petrol to T.V.O. should be carefully followed. When restarting the engine from cold, first drain the float chamber by means of the tap provided. Failure to do this will result in wetting the spark plugs. In any case, a start from cold will not be possible on pure vaporizing oil. Parts lists for these carburetters can be supplied on application; please give the name and type of the vehicle concerned. In any query always quote the reference letter and figures stamped on the fuel inlet boss.